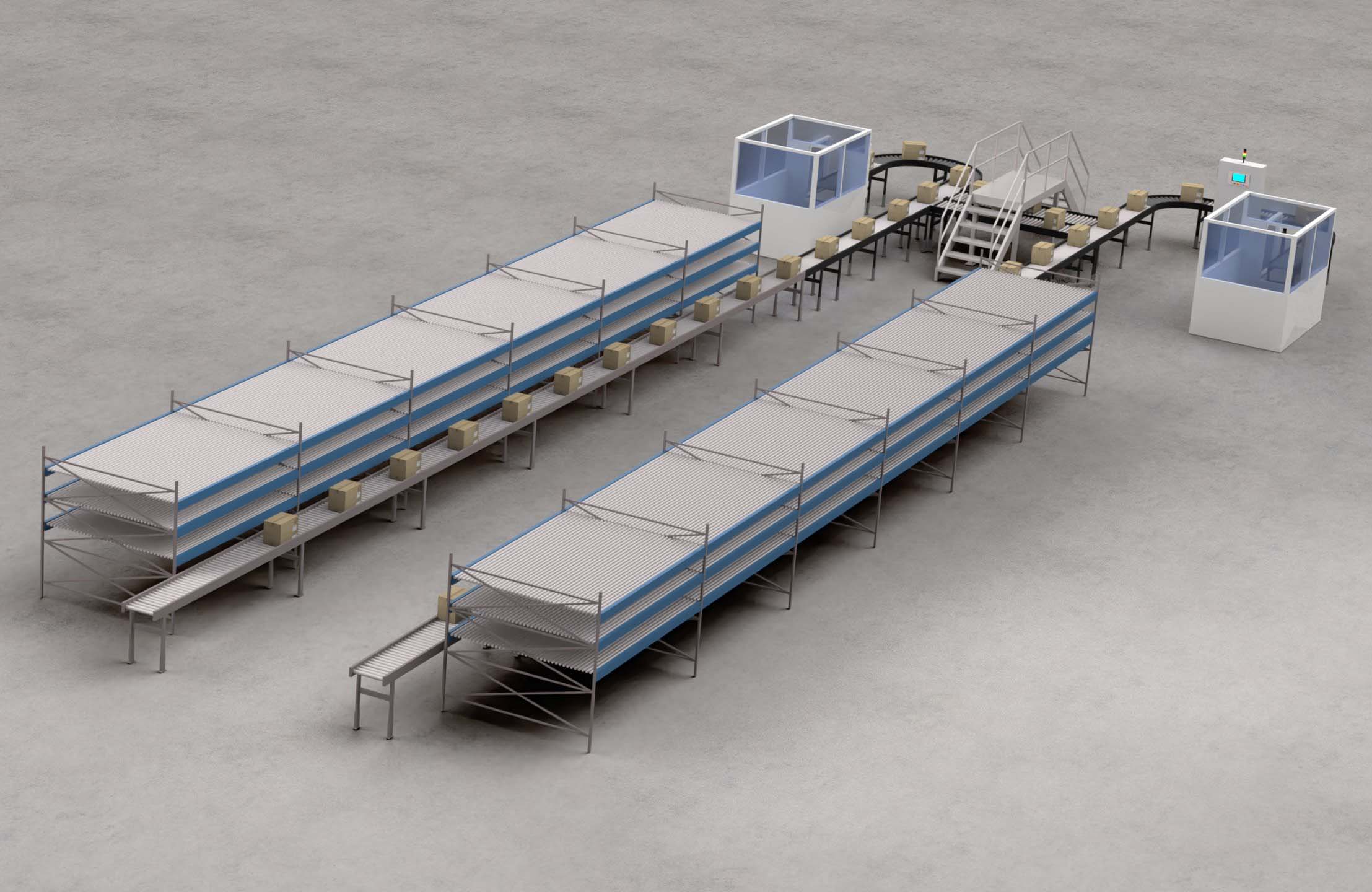

In the dynamic world of material handling and industrial automation, businesses are perpetually on the hunt for solutions that offer efficiency without compromising on sustainability. One such revolutionary solution is the 24v motorised roller conveyor system. This system, with its inherent energy recooperation capabilities, not only paves the way for efficient operations but also champions the cause of a green industrial ecosystem. Let’s delve into the specifics of this fascinating technology.

How Does a 24V Motorised Roller Conveyor Work?

At its core, a 24v motorised roller conveyor utilises individual motors within each roller. These rollers are driven by low-voltage DC motors, reducing the energy consumption that often accompanies traditional high-voltage systems. One of the significant benefits of such a design is the decentralisation of power, leading to reduced mechanical wear and lesser points of failure.

The Brilliance of Energy Recooperation

The standout feature of these conveyors is their energy recooperation capability. Here’s how it works: When power is cut to the motorised rollers, instead of this energy being wasted, the product’s inertia on the conveyor is utilised. This inertia, which would typically be dissipated as waste energy, is harnessed and converted back into usable energy. This stored energy is then utilised during startup, dramatically reducing the initial power surge that is common in most systems.

Benefits for the Business & the Planet

1. Energy Efficiency: The 24v motorised roller conveyors, by design, consume less energy than their high-voltage counterparts. When you couple this with the energy recooperation feature, you’re looking at significant energy savings, translating to decreased operational costs.

2. Reduced Carbon Footprint: As businesses increasingly aim to reduce their carbon footprint, adopting such energy-efficient systems contributes substantially. Reduced power consumption means less energy from fossil fuels, thereby resulting in fewer carbon emissions.

3. Operational Advantages: Beyond the environmental and cost benefits, these conveyors also offer operational advantages. The decentralised design means fewer points of failure, leading to reduced downtime and maintenance needs. Plus, with smoother startups due to stored energy, there’s less wear and tear on the machinery.

4. Flexibility and Scalability: Since each roller operates independently, it allows for more flexible system designs. As businesses grow and their needs change, these systems can be easily scaled or reconfigured without significant overhauls.

In Conclusion

Incorporating 24v motorised roller conveyors into an industrial setup is a definitive step towards an energy-efficient and sustainable operation. These conveyors, with their energy recooperation mechanisms, not only ensure operational efficiency but also reinforce a company’s commitment to sustainable practices.

As industries continue to evolve, so do the technologies that drive them. It’s a heartening sign when such innovations also respect our planet’s health and resources. So, the next time you come across a 24v motorised roller conveyor system, know that it represents a harmonious blend of efficiency, sustainability, and forward-thinking industrial design.

[/et_pb_text][/et_pb_column][/et_pb_row][et_pb_row _builder_version=”4.21.0″ _module_preset=”default” global_colors_info=”{}”][et_pb_column type=”4_4″ _builder_version=”4.21.0″ _module_preset=”default” global_colors_info=”{}”][et_pb_text _builder_version=”4.21.0″ _module_preset=”default” global_colors_info=”{}”]

Frequently Asked Questions (FAQ) about 24V Motorised Roller Conveyors

1. What is a 24V motorised roller conveyor? A 24V motorised roller conveyor is a system that uses individual low-voltage DC motors within each roller to move products. This decentralised power approach reduces energy consumption and mechanical wear, offering a more efficient and durable solution than traditional conveyor systems.

2. How does energy recooperation in these conveyors work? When power is cut to the motorised rollers, the product’s inertia on the conveyor is captured. Instead of this energy being wasted, it’s converted back into usable energy and stored. This stored energy is then utilised during startup, reducing the initial power surge and consumption.

3. How does this system reduce a company’s carbon footprint? By consuming less energy than traditional conveyor systems and recuperating energy that would otherwise be wasted, the 24V motorised roller conveyors contribute to reduced energy usage. Lower energy consumption results in fewer carbon emissions, especially if the energy source is fossil-fuel based.

4. Are there operational benefits to using this type of conveyor system? Absolutely. The decentralised design means fewer points of failure, leading to less downtime and maintenance needs. The system’s smoother startups, courtesy of the stored energy, also mean reduced wear and tear on machinery.

5. Can the system be scaled or reconfigured as business needs change? Yes, the independent operation of each roller allows for flexibility in system design. As business requirements evolve, the system can be easily scaled or reconfigured without extensive overhauls.

6. Is the initial investment higher for a 24V motorised roller conveyor? While the initial investment might be slightly higher compared to traditional systems due to the technology involved, the long-term energy savings, reduced maintenance, and increased lifespan often result in a lower total cost of ownership.

7. Are 24V motorised roller conveyors suitable for all industries? While they are versatile and can be used in many industries, it’s essential to assess individual operational requirements. They are especially beneficial for industries with high throughputs and those keen on energy efficiency and sustainability.

We hope this FAQ has provided clarity on the many benefits of 24V motorised roller conveyors. For any further questions or inquiries, feel free to reach out to our team.