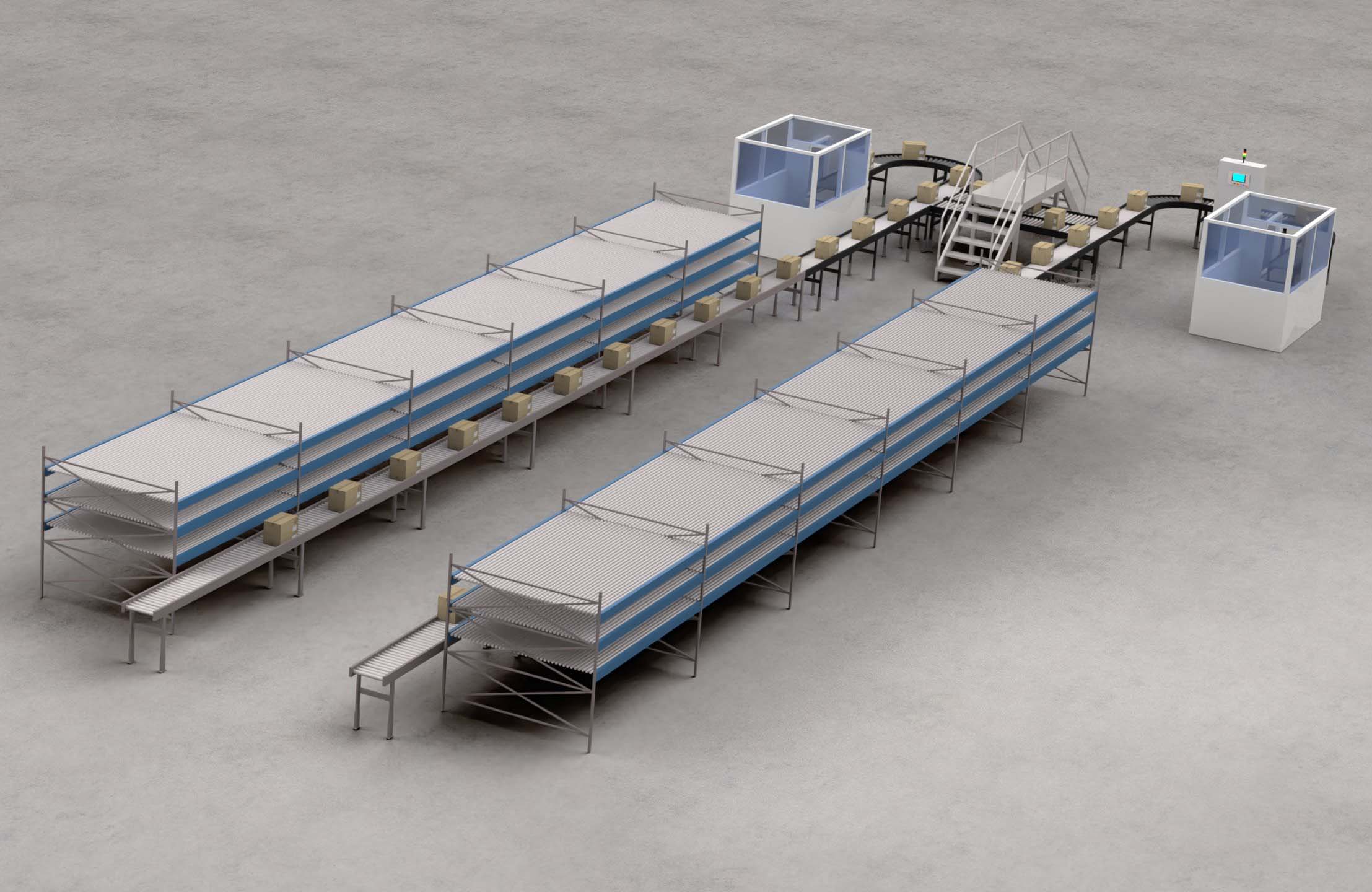

Automation systems are the backbone of efficiency in ecommerce, factories, fulfilment centres, and warehouses. When these systems encounter issues, it’s crucial to address them swiftly to minimise downtime and maintain productivity. The big question often arises: Should you opt for a DIY approach or call in our CSL engineers? This blog explains the key differences and why, in our humble opinion, CSL engineers are your best bet for maintaining your automation systems effectively.

The DIY Approach

The DIY approach might seem appealing due to the perceived cost savings and the immediate availability of your in-house team. However, there are significant challenges and risks associated with DIY repairs:

- Lack of experience and skills: Your team may not have the specialised training or experience required to accurately diagnose and repair complex automation systems. This can lead to incorrect fixes or even making the problem worse.

- Inadequate tools: Proper repair and maintenance of automation systems often require specialised tools and equipment. Your team may not have access to these, making it difficult to perform repairs effectively.

- Time constraints: Your team likely has other responsibilities and may not be able to dedicate the necessary time to address automation issues promptly. This can result in prolonged downtime and lost productivity.

- Safety concerns: Automation systems involve intricate electrical and mechanical components. Improper handling can pose serious safety risks to your team and your facility.

- Sourcing parts: Identifying and sourcing the correct parts can be challenging and time-consuming for an untrained team, further delaying the repair process.

The CSL Advantage

CSL engineers offer a comprehensive solution for maintaining and repairing your automation systems. Here’s why they are better placed to handle these tasks:

- Expertise and training: CSL engineers are fully trained and have extensive experience in dealing with various automation systems. They are adept at quickly diagnosing issues and implementing effective solutions.

- Proper tools and equipment: CSL engineers come equipped with the latest tools and technology needed for precise repairs, ensuring the job is done right the first time.

- Efficiency and availability: With their focused expertise, CSL engineers can rapidly identify faults and perform repairs in a timely manner, minimising downtime and disruption to your operations. When we agree to service your systems we will put a bespoke Service Level Agreement in place with you so you know when our engineers will be on site.

- Safety assurance: CSL engineers follow strict safety protocols and manufacturers’ guidelines, ensuring that all repairs are conducted safely and reliably.

- Reliable parts sourcing: Thanks to their extensive knowledge and industry connections, CSL engineers know what parts are needed and where to source them, reducing delays and ensuring the use of high-quality components.

Conclusion

While the DIY approach might initially seem cost-effective, the potential risks and inefficiencies can lead to greater expenses and operational disruptions in the long run. On the other hand, CSL engineers bring expertise, efficiency, and safety to the table, ensuring your automation systems are maintained and repaired to the highest standards.

Investing in CSL engineers for your automation repair needs not only safeguards your operations but also enhances the longevity and performance of your systems. Trust the professionals to keep your automation running smoothly, allowing you to focus on what you do best – growing your business.