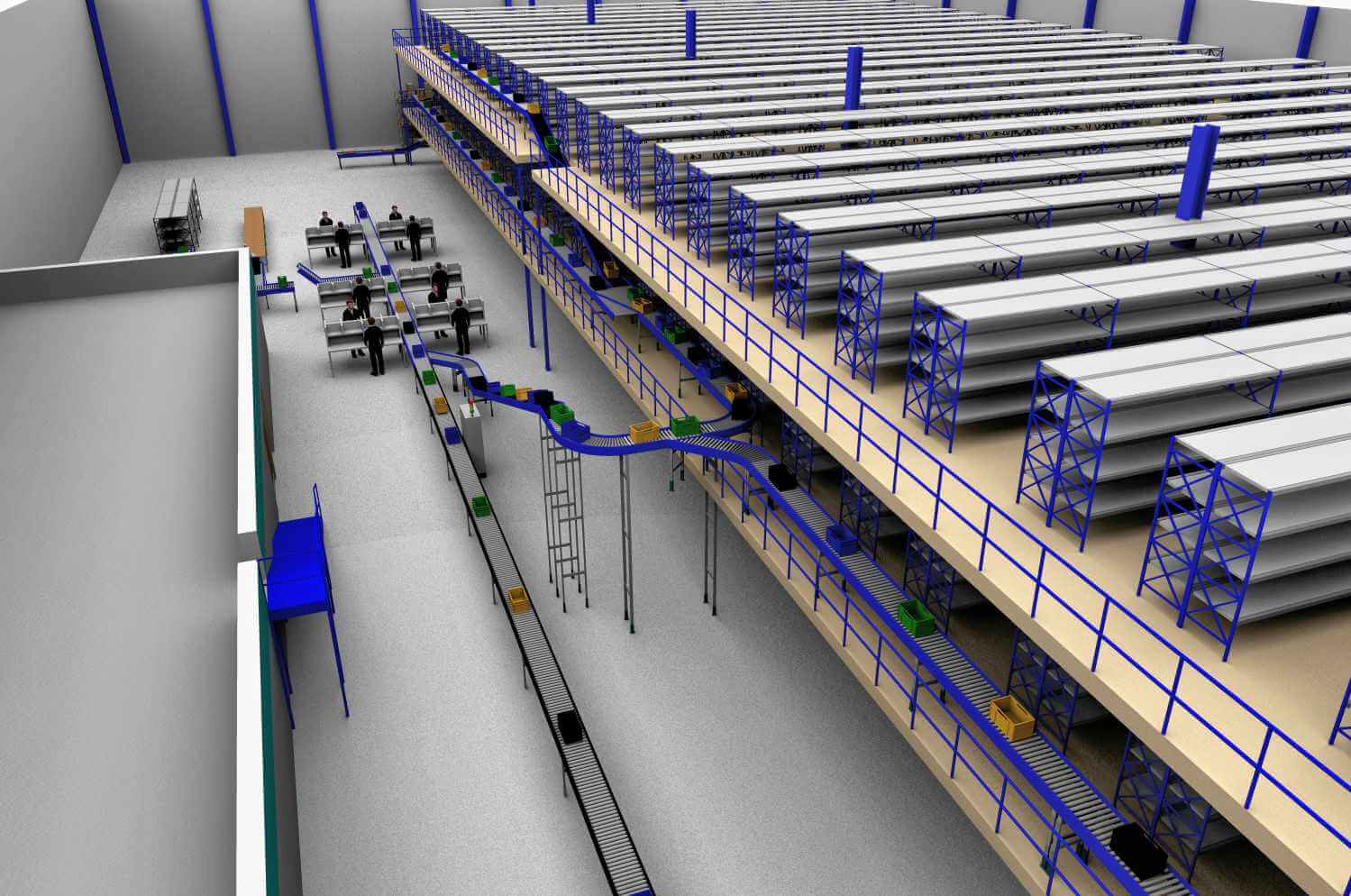

Aerospace Distribution Centre – Multi floor conveyor solution

A leading global aerospace parts supplier selected CSL to design and install a multi-floor conveyor system for their Midlands facility. The system included several areas working together as one cohesive solution.

In-bound parts, packed in cardboard cases, are transported to the first floor for stock replenishment, with the system designed to be reversible for flexibility. The order picking system handles both cardboard cases and tote bins, fed from the upper floors to the ground floor via an Ambaflex spiral that passes through a mezzanine opening. Non-contact accumulation was added to control product flow before the spiral.

The outbound system sorts five different colored tote bins, each with a specific destination, using color scanners to ensure accuracy. CSL integrated this system with a previously installed roller conveyor and added a color scanner for additional order picking.

Finally, an independent system feeds larger items from the first-floor mezzanine to the dispatch area. The installation of all four areas was done in stages to minimize disruption during normal operations.