Conveyor Systems Ltd post success handling Royal Mail Totes

In the evolving logistics sector, businesses must adapt to meet increasing demands and stay competitive. Royal Mail’s transition from cage trolleys and sacks to stackable plastic totes for transporting letters and direct mail has prompted many companies, including e-fulfilment and mailing service providers, to update their handling systems.

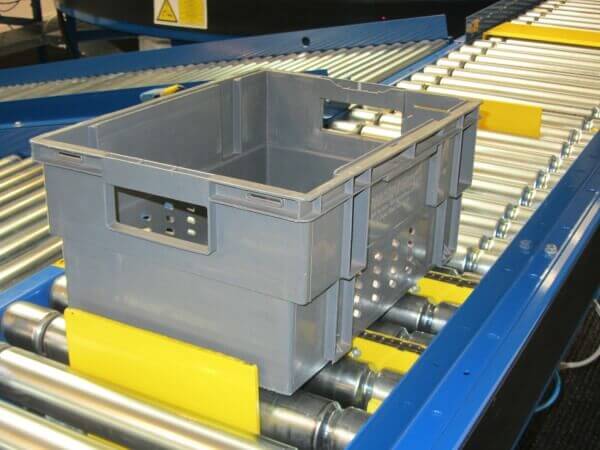

Conveyor Systems Ltd (CSL), a leading UK conveyor provider, was tasked with engineering a solution to assist a Direct Mailing house in making this transition. CSL designed an automated conveyor system to move products from collating and wrapping machines into Royal Mail totes. The system efficiently delivers empty totes to machines and conveys full totes for labelling and dispatch at speeds of up to 100 totes per minute.

With CSL’s expertise in tote handling conveyors and warehouse solutions, the customer benefited from increased throughput, improved handling capacity, and reduced operating costs. CSL’s experience in e-commerce and warehouse systems, including non-contact accumulating conveyors, sortation systems, and vertical elevators, made them the ideal partner for this project.