Automated Order Picking Systems

Enhancing Order Picking Efficiency with Conveyor Systems

In the fast-paced realm of eCommerce and third-party logistics (3PL), optimising order picking processes is key to maintaining operational efficiency and meeting customer demands. The strategic integration of conveyor systems can significantly improve the order picking process and offers a huge range of benefits that streamline order fulfilment.

What Are Automated Order Picking Systems?

Order picking encompasses the crucial task of selecting items from inventory to fulfil customer orders. It involves the movement of goods and materials through warehouses or distribution centres to locate, retrieve, and package items accurately and efficiently. As the backbone of fulfilment operations, any improvements in the order picking process directly translate to enhanced productivity and customer satisfaction. Some technologies used in automated order picking systems include:

- Robotics and Automation: These systems leverage cutting-edge robotics and automation technology to efficiently navigate warehouse spaces and retrieve items or products required for specific orders.

- Warehouse Management Software (WMS) Integration: Integrated with sophisticated software, these systems communicate and synchronise with warehouse management systems. This integration ensures precise and accurate picking, inventory management, and order tracking.

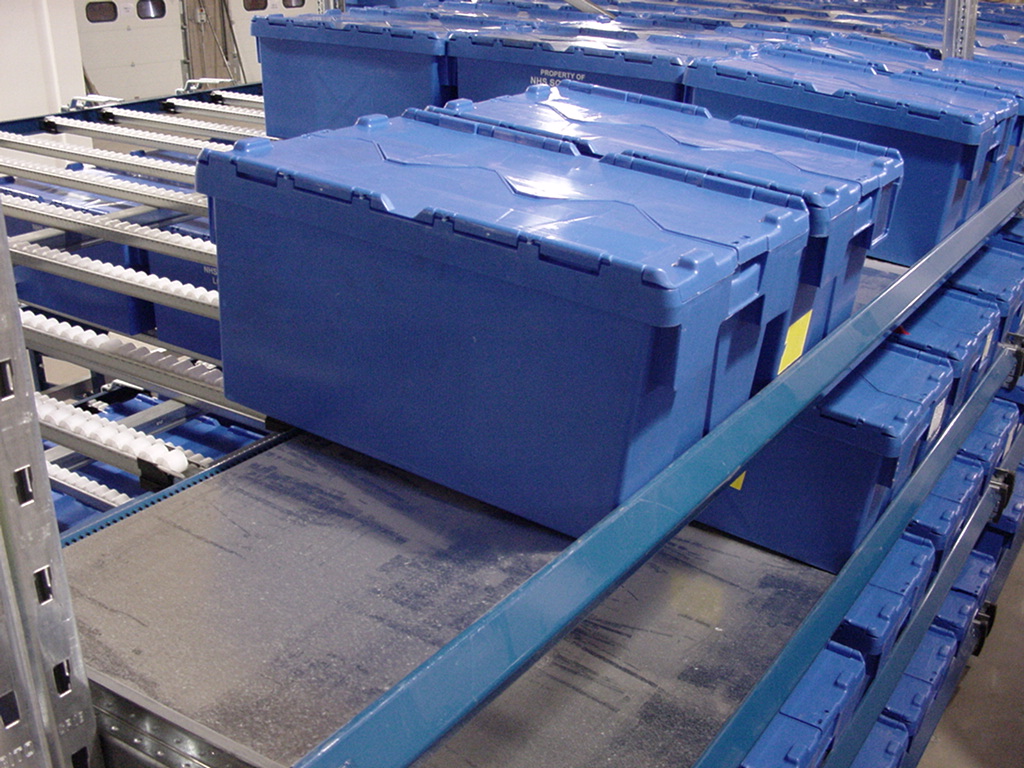

- Highly Configurable Conveyors and Sorting Technology: Automated order picking systems utilise conveyors and sorting technology, allowing for the smooth movement of items within the warehouse or distribution centre. These systems are highly configurable and can be tailored to suit various product shapes, sizes, and weights.

- Picking Accuracy and Efficiency: By utilising advanced algorithms and smart technologies, these systems ensure optimal picking accuracy, significantly reducing errors and enhancing efficiency in order fulfilment.

- Scalability and Flexibility: The systems are designed with scalability in mind, adapting to the changing needs of businesses, accommodating increased order volumes, and expanding product lines.

How Our Automated Order Picking Systems Work

Our Automated Order Picking Systems at Conveyor Systems streamline the order fulfilment process with precision and efficiency. Upon order initiation, our systems seamlessly integrate with your Warehouse Management Software (WMS), swiftly processing the order details in real-time.

Utilising advanced algorithms and robotics, our systems navigate through the warehouse, identifying and retrieving the required items with pinpoint accuracy. Once picked, items smoothly travel via our configurable conveyor systems to a centralised area for packing or shipping, efficiently managed by sorting technology.

The system conducts quality checks such as check weighers and seamlessly integrates with packaging technology, ensuring accurate and timely order packaging. Real-time tracking and reporting provide insights into order status and inventory levels. Continuously optimised for adaptability, our systems revolutionise order-picking operations, offering businesses a competitive edge with enhanced efficiency and error-free order fulfilment.

Read more about our process.

Benefits of Implementing Automated Order Picking

Reducing pick times: Conveyor systems operate continuously, eliminating the need for manual transportation of goods between pick locations and packing areas. This constant flow ensures a steady pace of order fulfilment, significantly reducing processing times and increasing throughput.

Improved accuracy: By standardising and automating the movement of items, conveyor systems mitigate the likelihood of errors associated with manual handling. Each product follows a predefined path, minimising the risk of misplacements or incorrect picks, thereby enhancing order accuracy and reducing costly returns.

Optimised space utilisation: Leveraging vertical and horizontal space within the warehouse, conveyor systems, such as spiral conveyors, maximise storage capacity while maintaining accessibility to inventory. This strategic utilisation of space facilitates efficient order picking by minimising the time required to locate and retrieve items, even in high-density storage environments.

Employee safety: Manual handling of heavy or bulky items poses inherent risks to employee well-being. Conveyor systems alleviate physical strain by automating the transport of goods, reducing the need for repetitive lifting and carrying. This not only mitigates the risk of workplace injuries but also fosters a safer and more ergonomic working environment.

Scalability and flexibility: As e-commerce and 3PL companies adapt to evolving market demands, scalability becomes imperative. Conveyor systems offer the flexibility to scale operations seamlessly, accommodating fluctuations in order volumes without compromising efficiency or accuracy.

Order Picking FAQs

What industries can benefit from Automated Order Picking Systems?

Automated Order Picking Systems cater to a wide range of industries, including but not limited to e-commerce, retail, distribution centres, manufacturing, pharmaceuticals, and more. These systems are versatile and adaptable to various business models requiring efficient material handling.

Are these systems customisable to suit specific business needs?

Yes, our systems are highly customisable. We understand that every business has unique operational requirements. Our solutions are designed to be adaptable, allowing customisation to meet specific needs and workflows.

How do these systems integrate with existing warehouse management software?

Our Automated Order Picking Systems are designed for seamless integration with various warehouse management software. This integration ensures real-time communication and synchronisation, providing accurate inventory management and order tracking.

Can these systems handle different types of products and packaging?

Absolutely. Our systems are versatile and can handle various product shapes, sizes, and weights. They are designed to accommodate diverse product types and packaging, ensuring efficiency and accuracy in order fulfilment processes.

What level of support and maintenance do you provide for these systems?

We offer comprehensive support and maintenance for our Automated Order Picking Systems. Our dedicated team ensures that your system operates optimally, minimising downtime and maximising productivity. Our support covers troubleshooting, regular maintenance, and system upgrades.

How scalable are these systems for growing businesses?

Our systems are inherently scalable and capable of adapting to business growth and increased order volumes. Whether you’re experiencing an increase in demand or expanding your product lines, our solutions are designed to evolve with your business requirements.

What are the primary benefits of implementing Automated Order Picking Systems?

Implementing our systems offers numerous benefits, including increased operational efficiency, reduced errors in order fulfilment, minimised labour costs, optimised space utilisation, and a streamlined order-picking process leading to higher customer satisfaction.

Transform Your Order Picking Process with Conveyor Systems

In the dynamic landscape of e-commerce and 3PL operations, the integration of conveyor systems emerges as a pivotal strategy to optimise order picking processes. By enhancing efficiency, accuracy, and employee safety, these systems empower operations managers to meet the escalating demands of modern commerce while maintaining a competitive edge in the industry.

Conveyor Systems Ltd. stands as an industry-leading integrator, boasting over 25 years of unparalleled expertise in conveyor and automation solutions. We specialise in crafting tailored solutions, utilising state-of-the-art robotics and automation technology to ensure precision, efficiency, and reliability in order fulfilment. Our systems are not just cutting-edge; they are highly customisable and scalable, designed to seamlessly adapt to the unique operational requirements of businesses while accommodating expansion and increased order volumes.

Equip your business with the latest order-picking technology! Contact us today to explore how our Automated Order Picking Systems can revolutionise your business.

In the dynamic landscape of e-commerce and 3PL operations, the integration of conveyor systems emerges as a pivotal strategy to optimise order picking processes. By enhancing efficiency, accuracy, and employee safety, these systems empower operations managers to meet the escalating demands of modern commerce while maintaining a competitive edge in the industry.

In essence, investing in conveyor systems not only streamlines order fulfilment but also lays the foundation for sustained growth and operational excellence in the ever-evolving landscape of logistics and supply chain management.