Introduction

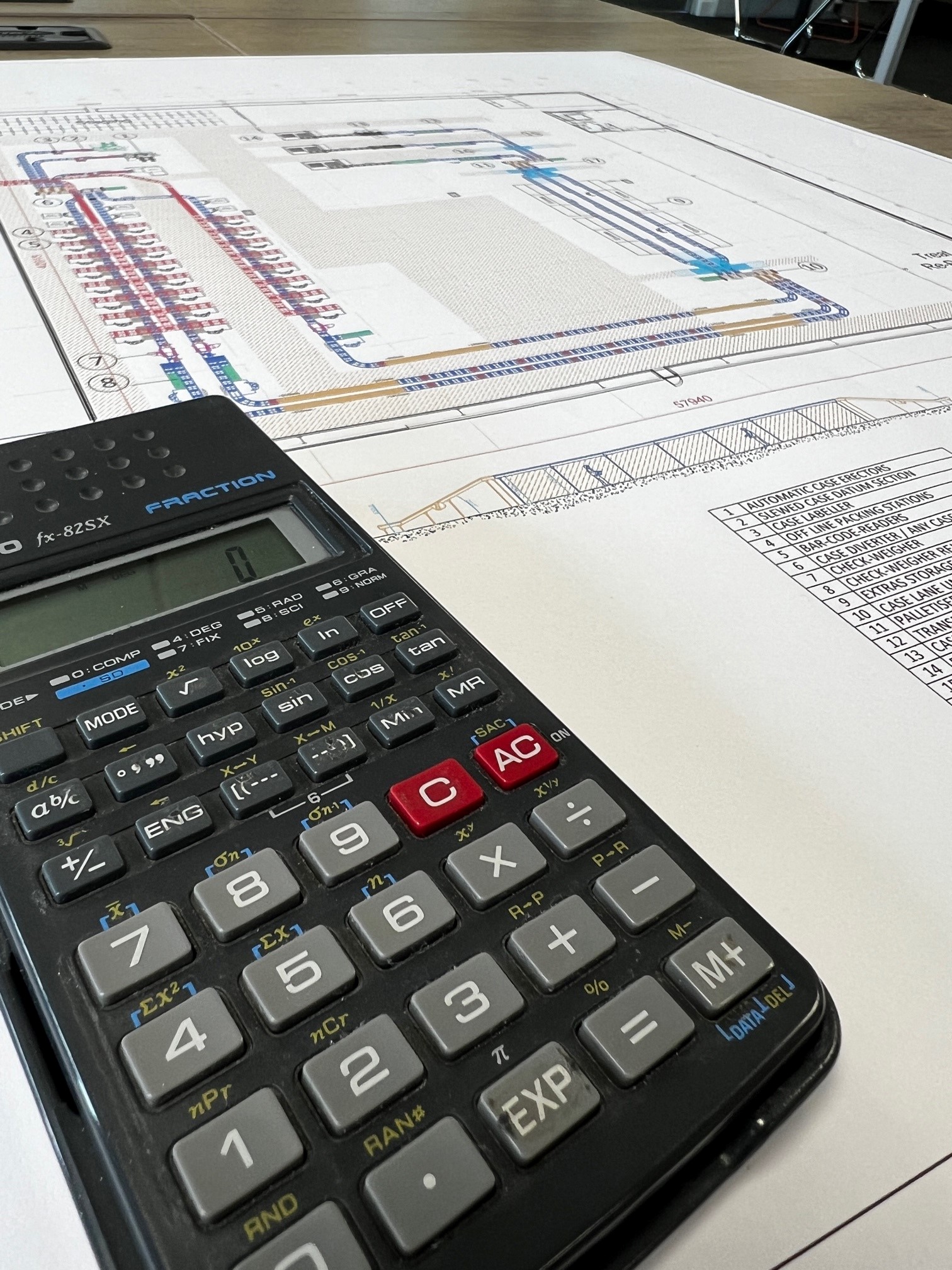

In the fast-paced world of logistics and ecommerce, the efficiency of warehouse operations can make or break a company’s competitive edge. As an Operations or Facilities Director within a 3PL or ecommerce company, the decisions made during the planning, designing, and building phases of a warehouse are pivotal. One critical aspect often overlooked is the integration of automation and conveyor systems. In this blog, we’ll explore why it’s essential to consider these elements from the outset and how they can profoundly impact warehouse efficiency and productivity.

Early integration for enhanced efficiency:

Due to the complexity of planning, designing, and building a new warehouse facility it’s not uncommon for the planning for automation and conveyor systems to start once the building design is confirmed and approved. Whilst it is absolutely possible for automation systems to be designed to fit the available space it can, on occasion, lead to compromise or restrictions of the options available, which in turn can lead to suboptimal utilisation of space.

By incorporating these systems early in the planning phase, warehouses can be designed with the automation, storage and flooring layouts optimised for seamless automation integration.

This proactive approach minimises disruptions, reduces retrofitting costs, and maximises operational efficiency from day one. It can also result in the need for less space needed for storage or automation systems enabling you to more effectively use the available space, for example for a larger office space.

Tailored design for optimal automation

Every warehouse has unique operational requirements and workflows. Designing with automation in mind allows for customisation to suit specific needs.

Custom-built conveyors and automation systems can be seamlessly integrated into the warehouse layout, significantly reducing bottlenecks and maximising throughput.

By aligning the building design with automation needs, companies can achieve higher levels of efficiency and scalability, future-proofing their operations.

Space optimisation and flexibility

Automation-friendly designs enable better utilisation of space, allowing for higher storage densities and more efficient material flow.

Strategic placement of conveyors, mezzanine flooring, and racking systems can make far better use of the available space and allowing flexibility for future expansion or modifications.

Planning for scalability ensures that the warehouse can adapt to changing business needs and evolving market dynamics without significant disruptions.

Cost-efficiency and ROI

While upfront costs may be higher when integrating automation into warehouse design, the long-term benefits far outweigh the initial investment.

Enhanced operational efficiency leads to cost savings through reduced labour requirements, improved inventory management, and faster order fulfilment.

A well-designed automated warehouse delivers a higher return on investment (ROI) by increasing throughput, minimizing errors, and enhancing customer satisfaction.

To find out more about how Conveyor Systems Ltd can help your business deal with returns contact us on 01283 55 22 55 or email [email protected]/

CSL can help

The modern warehouse is more than just a storage facility; it’s a dynamic hub of logistical operations. By recognising the importance of early integration of automation and conveyor systems in warehouse planning, operations directors can unlock significant efficiency gains and competitive advantages.

Strategic design considerations tailored to automation needs ensure optimal space utilisation, scalability, and cost-efficiency. As the eCommerce landscape continues to evolve, proactive planning and investment in automation will be essential for staying ahead of the curve and meeting growing customer expectations.

By adopting a forward-thinking approach to warehouse design, operations directors can position their companies for long-term success in an increasingly automated world.

We have worked with many organisations across a wide variety of sectors, so we understand the importance of getting the design and planning right when it comes to your automated processes. We will work with you at whatever stage you’re at and can help improve your throughputs, help you to avoid errors.

If you’re in the process of planning your new warehouse facility, looking to extend your current operations or simply investigating how to improve your operational efficiencies with automation get in touch with us on 01283 55 22 55 or email [email protected]