Vertical Elevator Conveyors Systems

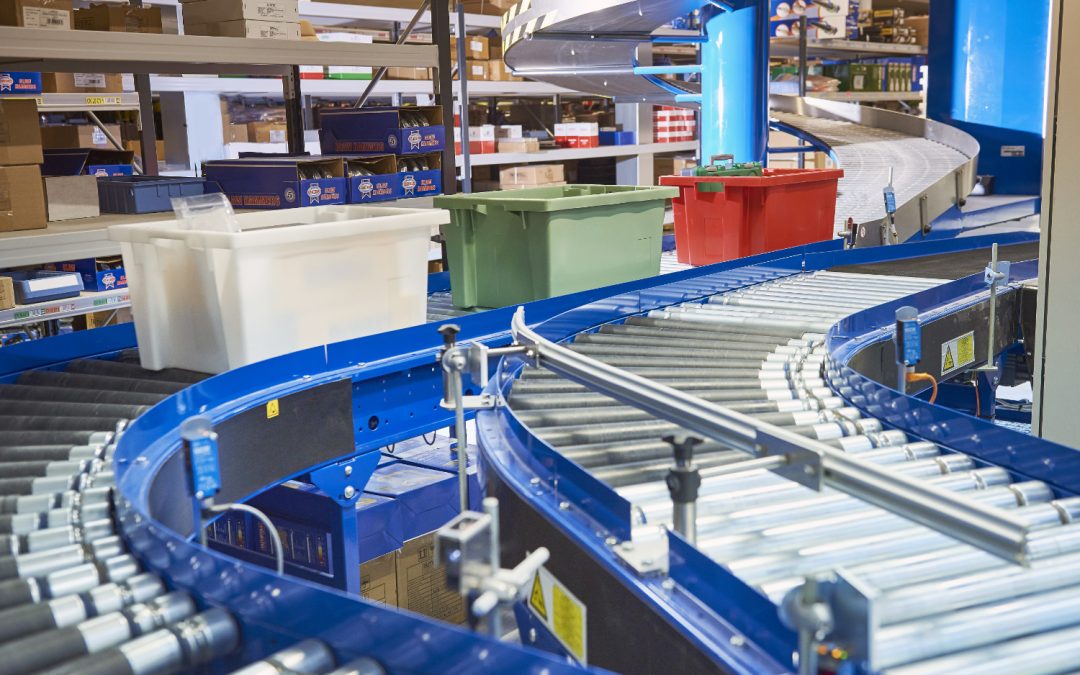

At CSL Automation, we understand the evolving demands of modern industries and the role vertical lift conveyor systems play in ensuring smooth, efficient operations. Our expertly made vertical machinery is thoughtfully designed, offering space-saving solutions with a minimal footprint – a valuable attribute in today’s space-conscious industries.

A vertical elevator guarantees the safe transit of goods between varied heights or multiple floors. Our systems adeptly manage a diverse range of products with their versatile design, from boxes, crates, and totes to sacks, pallets, and more.

You don’t have to compromise on throughput either! Our vertical conveyor systems are capable of handling up to 2,000 products per hour at a maximum of 25m in height, whether it’s a light 75kg product or a 2-ton pallet.

Types of vertical lift conveyor solutions:

1. Qimarox® platform elevators (MK1)

The Qimarox Prorunner Mk1 is a high-quality, robust vertical elevator that remains versatile while keeping a minimal footprint. The Prorunner Mk1 comes in multiple configurations to suit the application and products. The lift uses a durable, low-maintenance belt, which does not require lubricating or tightening, unlike chain lifts. In and out feeds can be either from right angles or from the front, allowing for additional flexibility. Choose from motorised rollers or an optional grip top belt to get the most out of your vertical conveyor system.

Specification

- Up to 420 products per hour

- Available up to 11.4m high

- Max product size: 1200x600mm

- FootPrint: 0.7m²

- Suitable for boxes, crates, totes, sacks etc

- Max product weight: 75kg

- Low noise

2. Qimarox® continuous elevators (MK5)

The Qimarox Prorunner Mk5 is a high throughput vertical lift conveyor with ultra-smooth continuous movements and transfers. The Prorunner Mk5 comes in multiple configurations to match the application and products of your business. With a high-quality and low maintenance chain, you don’t need to worry about constant maintenance. This lift conveyor also allows for in and out feeds to be installed from either right angles or from the front. This particular elevator conveyor system can be used as a vertical sortation/buffer system.

Specification

- Up to 2000 products per hour

- Available up to 25m high

- Max product size: 1000x650mm

- FootPrint: 1.1m²

- Suitable for boxes, crates, totes, sacks etc

- Max product weight: 50kg

3. Qimarox® pallet elevators (MK9)

The Qimarox Prorunner Mk9 is a sturdy and hard-wearing vertical pallet conveyor which can be fitted with either roller or chain lifting platforms. This vertical conveyor can be customised in various configurations to fit the applications of your business and its products. With in and out feeds that can be installed from either right angles or from the front, this versatile lift conveyor can increase the efficiency of your business operations. The Prorunner Mk9 can also be used as a vertical sortation/buffer system.

Specification

- Up to 60 pallets per hour

- Available up to 10m high

- Max product size: 1200x1200mm

- FootPrint: 3m²

- Suitable for pallets, pallet boxes, cases, IBC etc

- Max pallet weight: 1000kg

- Low noise

4. Qimarox® pallet elevator (MK10)

The Qimarox Prorunner Mk10 is a dependable vertical 4-post pallet conveyor that can be fitted with either roller or chain lifting platforms. As the Prorunner Mk10 can be arranged into multiple configurations, you can have peace of mind that we can tailor this vertical conveyor system to your businesses needs. Out feeds can be either from right angles or from the front/back. You can also use this vertical lift conveyor as a vertical sortation/buffer system.

Specification

- Up to 60 pallets per hour

- Available up to 10m high

- Max product size: 1200x1200mm

- FootPrint: 3m²

- Suitable for pallets, pallet boxes, cases, IBC etc

- Max pallet weight: 2000kg

- Low noise

Key benefits of using Qimarox® vertical lift systems:

In the realm of conveyor and automation solutions, Qimarox® stands out as a brand aligned with precision, durability, and adaptability. Here are their unparalleled benefits:

- Low maintenance requirements: Designed with the user in mind, these systems promise prolonged functionality with minimal upkeep.

- High-quality, robust build: Ensuring longevity, each unit showcases a sturdy construction, reflecting our commitment to quality and reliability.

- Multiple configuration options: Catering to diverse needs, we offer configurations tailored to various applications, emphasising flexibility in design.

- Right-angle or front-feed options: You can choose right-angle or front-feed mechanisms to suit distinct spatial and operational requirements.

- Use as vertical sortation or buffer systems: Beyond just lifting, these systems can be integrated for vertical sortation or as reliable buffer solutions, enhancing warehouse efficiency.

With CSL and Qimarox®, elevate your warehouse operations to unmatched heights.

Save on vital warehouse space with a vertical elevator conveyor system today

At CSL Automation, we want you to get the most out of your facility. That’s why we have a range of vertical conveyor systems to help you increase the available space in your warehouse, enhance efficiency and easily transport boxes, pallets and more. If your warehouse is in need of a vertical lift conveyor, get in touch with our team today and we can get started on creating a tailored elevator conveyor system for your business.

FAQs:

What are vertical lift conveyors?

Vertical lift conveyors are systems designed to move products vertically between different heights or floors, saving space and improving efficiency.

How is a continuous vertical lift conveyor different from standard vertical lifts?

Continuous vertical lifts, like the Prorunner Mk5, offer ultra-smooth continuous movements and transfers, providing higher throughput rates and efficient sorting capabilities.

Can I customise my vertical conveyor elevator based on my application needs?

Yes, the Qimarox® vertical lift systems have multiple configurations to suit varying application and product requirements.

How do I decide between a belt or chain lift system?

The choice depends on your product type, weight, and throughput needs. Like in Prorunner Mk1, belts require less maintenance as they don't need lubrication or tightening, while chains, used in Prorunner Mk5, can handle higher weights and throughput.

What products can be transported using the vertical lift conveyor systems?

Our systems can transport various products, including boxes, crates, totes, sacks, pallets, pallet boxes, cases, and IBCs.

How high can a vertical lift conveyor elevate products?

Depending on the model, our systems can elevate products up to a height of 25m.

Latest Blog Posts

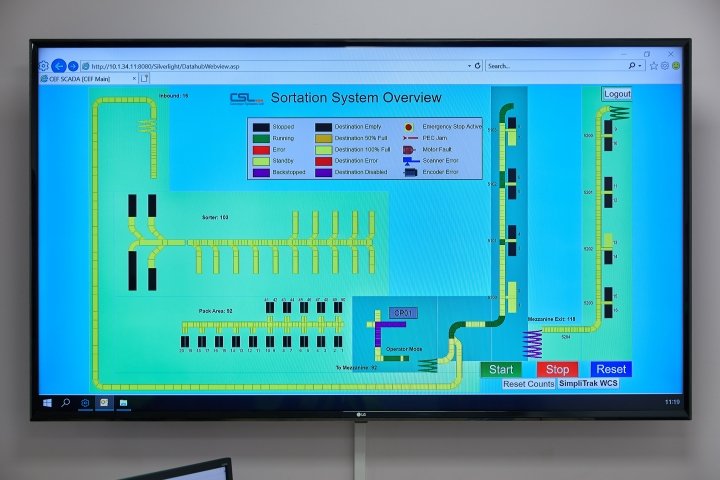

Why updating the software for your automation system’s HMI is vital

The Human Machine Interface (HMI), the vital control panel that allows your operators to monitor and interact with the machinery.

How to justify having a service contract for your business

A key component of safeguarding automation systems is having a robust service contract in place.

Customising maintenance plans with CSL Automation’s ConveyorCare

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and lost revenue.

Hybrid Fulfilment: Revolutionising retail with automation

Supported by cutting-edge automation, hybrid fulfilment enables businesses to achieve efficiency, flexibility, and scalability while delivering exceptional customer experiences.

Why updating the software for your automation system’s HMI is vital

The Human Machine Interface (HMI), the vital control panel that allows your operators to monitor and interact with the

How to justify having a service contract for your business

A key component of safeguarding automation systems is having a robust service contract in place.

Customising maintenance plans with CSL Automation’s ConveyorCare

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and

Hybrid Fulfilment: Revolutionising retail with automation

Supported by cutting-edge automation, hybrid fulfilment enables businesses to achieve efficiency, flexibility, and scalability while delivering exceptional customer experiences.

Is now the right time for a new conveyor and automation system?

As we step into a new year, it’s the perfect time to reflect on operational efficiencies and plan ahead

Keeping operations running smoothly post peak

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and

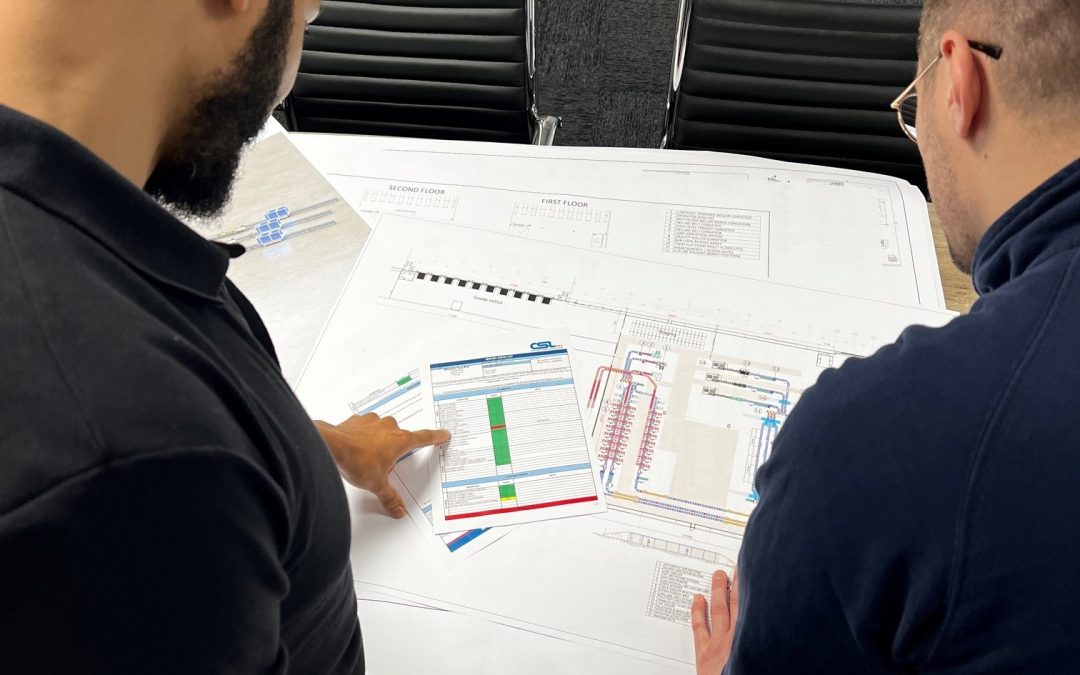

Creating relationships that last

We are proud to have completed installations over more than 25 years for many major organisations. We have forged strong relationships and continue to provide automation solutions through ongoing maintenance or follow-on projects. Constantly working with our customers to meet and exceed their needs.

“I have found working with CSL the ideal partnership, they understood the brief and worked closely with CEF to ensure the design met all of the criteria. The support from start to finish was excellent. The project ran smoothly from start to finish. The system has made our new warehouse very efficient and allowed us to increase the throughput”

“As this was a new facility it was difficult to visualise the conveyor system prior to the mezzanine floor installation, but CSL provided a detailed 3D drawing which included both the mezzanine and the conveyors which brought clarity to this. The install process was smooth and the end results have allowed us to increase control, flexibility & volumes”

“We have worked with CSL previously and after many years of reliable operation we decided to use CSL again to design, supply and carry out the installation. As with the last system the benefits became almost immediately evident”