Automation solutions for factories

Solutions tailored to your needsSolutions for factories

Automation has become a critical force in revolutionizing factory operations, enhancing productivity, and improving the speed and accuracy of your manufacturing processes.

At CSL Automation, we specialise in designing and installing state-of-the-art systems that drive superior efficiency and precision in factory environments. Our automated solutions, including control systems, scanning and conveyor technologies, are engineered to optimise your production line and elevate your factory’s performance.

Discover how CSL Automation can help you streamline operations and stay competitive in today’s fast-paced industrial landscape.

Offering Tailored Automation Solutions

It’s vital to get a system that works for you abnd your business requirements. It spans from simple product transfers between assembly or workstations. To more complex end-of-line processes involving packing, labelling, wrapping, and palletising. Even seemingly modest conveyor projects can provide significant benefits within a short timeframe. Yet, automation hardware is only as effective as the controlling software behind it. We offer a suite of control and integration packages to ensure seamless operation within your business.

Our offerings include;

- Production data and reporting capabilities

- Product and material movement within your factory

- Seemless connecting key elements of your machinery

We commit to ensuring that our hardware and software work in harmony with your solutions.

Automation in factories

The integration of automation in factory operations has become an essential requirement in today’s manufacturing landscape. Benefits include:

- Enhanced efficiency: Embrace automated systems to minimise human errors and optimise workflow, ultimately enhancing overall operational efficiency within the factory.

- Cost reduction: Significantly lower operational costs by automating tasks that were once labour-intensive, leading to a more cost-effective manufacturing process.

- Enhanced accuracy: The right automation system can help you achieve precise handling and movement of products and materials within your factory. This means fewer errors, maximised accuracy, and ultimately improved customer satisfaction by ensuring consistent and reliable production and consistently accurate deliveries.

- Scalability: Easily adapt to fluctuating demands by scaling up your automated systems, providing a flexible and responsive solution to meet the dynamic needs of the manufacturing environment.

In addition automation in factories can offer:

- Reduced personnel and MHE movements: Streamline your processes by minimising the need for manual labour and material handling equipment (MHE) manoeuvres.

- Improved production output: Boost productivity and meet growing demands with automated workflows.

- Reduced manual handling aspects: Enhance workplace safety by minimising manual handling tasks, reducing the risk of injuries.

- Creation of space/storage/buffer areas: Maximise available space with intelligent storage and buffering solutions, optimising your facility layout.

- Elevation to a high level for increased production space/access: Utilise vertical space efficiently to expand production capabilities without expanding your footprint.

- Increased efficiencies and accuracies: Achieve higher levels of precision for better product quality and customer satisfaction.

- Lower operational costs: Save on labour and operational expenses, ensuring a rapid return on your investment.

- Addition of mezzanine floors for increased production space: Our solutions can include mezzanine floors, enhancing your facility’s capacity while maintaining a compact footprint.

Essential elements for automation in factories

The success of automation in factories hinges on critical components that foster efficiency and innovation:

- Factory Control System (FCS): Acts as the orchestrator for operations, synchronising equipment, and ensuring a seamless workflow within the factory environment.

- Automated machinery: Encompassing solutions for order picking, storage, and distribution operations, a variety of automated machinery elevates accuracy and boosts overall productivity on the factory floor.

- Integration: Seamlessly unite your Factory Management System (FMS) with FCS to optimise the core of your automation initiative, ensuring a harmonised and efficient operation within the factory setting.

The ROI of warehouse and distribution automation

Over time you can benefit from substantial cost savings an automated processes will offer through reduced labour costs, operational inefficiencies, and error-related costs.

One of the biggest challenges in a factory can be delays in production if parts are incorrectly or partially picked for product assembly. Automation systems can resolve this issue effectively to ensure that all the correct components are delivered at the right time to enable quick and accurate assembly. This means that your operations can flow consistently and speed up the whole process and reduce the need for production to slow down or stop.

Tailored warehouse solutions for your needs

At CSL, we pride ourselves on delivering adaptable and versatile solutions that cater to your specific demands. Our offerings seamlessly align with the requirements of diverse business scales and types, whether you’re a nimble start-up or a well-established enterprise. With a focus on adaptability and customisation, we ensure that our factory and production solutions perfectly match your unique requirements, fostering efficiency and growth across the board.

Our Automation & Conveyor Solutions

We work closely with the industry leaders in conveyor and automation systems to provide the quality, reliability and durability required. Ensuring all projects are completed to the highest possible standard.

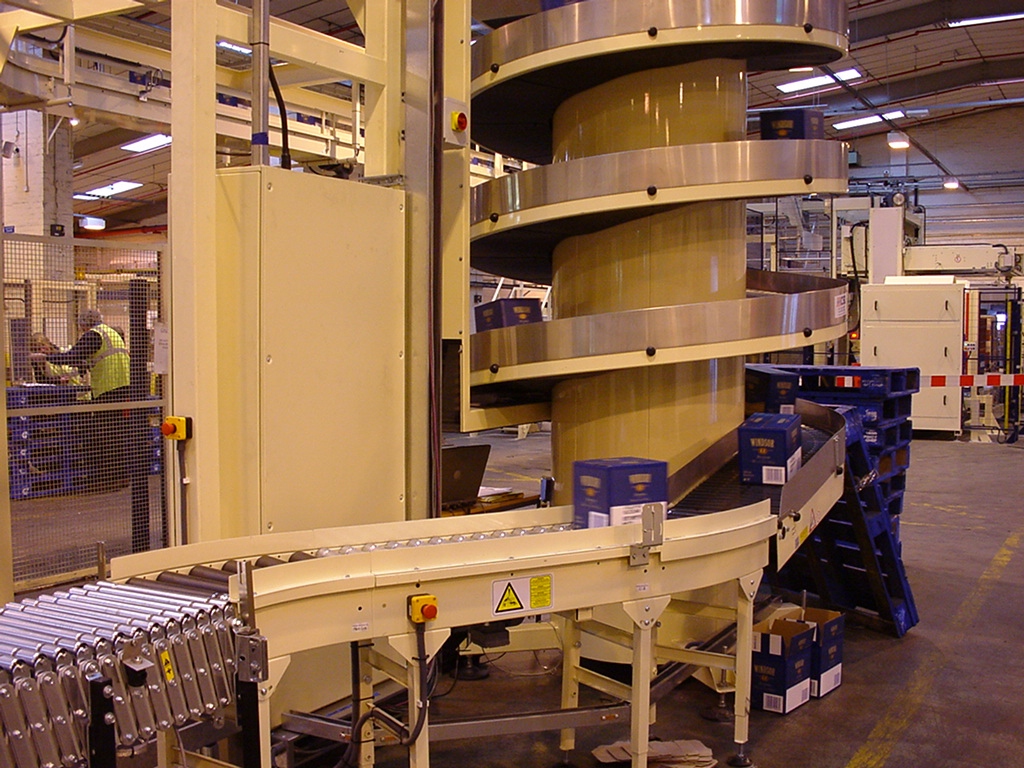

We have a wide range of modular and bespoke conveyor systems to provide customers with maximum flexibility, tailoring designs to your individual handling applications and budgets. Layouts can be designed to integrate with existing conveyor systems and associated equipment.

Our conveyor system project team can assess individual requirements, however complex, and then design and construct the most efficient solution whilst remaining cost-effective and within budget.

Belts and Conveyors

Spiral Conveyors

Automated Sortation

Automated Packing

Pallet Conveyors

Vertical Storage

AMRs

Vertical Lifts

Mezzanines, goods lifts & pallet racking

Latest Blog Posts

The benefits of Pick to Light

Pick to Light can be a game changer for yor facility when it comes to swift and accurate order picking.

Integrators vs. Manufacturers

When embarking on an automation project, one of the fundamental choices you’ll need to make is between working with an integrator or a manufacturer.

Enhance your 2025 automation strategy: Boost throughput, accuracy, and speed

With 2025 soon to be upon us the pressure on operations managers and directors to increase efficiency has never been higher.

Prepare your systems for a smooth post-peak season with CSL automation’s health check services

As the post-peak season approaches imminently, it's crucial to ensure that your automation and conveyor systems are in top shape.

The benefits of Pick to Light

Pick to Light can be a game changer for yor facility when it comes to swift and accurate order

Integrators vs. Manufacturers

When embarking on an automation project, one of the fundamental choices you’ll need to make is between working with

Enhance your 2025 automation strategy: Boost throughput, accuracy, and speed

With 2025 soon to be upon us the pressure on operations managers and directors to increase efficiency has never

Prepare your systems for a smooth post-peak season with CSL automation’s health check services

As the post-peak season approaches imminently, it's crucial to ensure that your automation and conveyor systems are in top

How the UK budget’s National Insurance changes impact businesses

With the recent increase in National Insurance contributions, businesses with large manual workforces face higher employment costs. CSL Automation

The risks of a broken or damaged conveyor system

We understand that you are constantly seeking ways to improve operational efficiency and reduce costs. So why would you

Creating relationships that last