Warehousing & Distribution Centre Automation

Keeping your products movingAutomated Warehouse Solutions

Warehouse automation plays a pivotal role in transforming operational efficiency and improving processes.

Unlock the potential of your warehouse automation with solutions designed to boost capacity, improve precision, and ensure operational reliability—all while driving down costs and reducing health and safety risks for your workforce.

CSL Automation can deliver tailored projects to suit your business requirements, now and in the future.

Warehouse Conveyor Automation

Automating warehouse operations is a necessity in modern warehouses. The benefits include:

- Enhanced efficiency: Automated systems minimise human error and optimise workflow, boosting overall efficiency.

- Cost reduction: By reducing labour-intensive tasks, operational costs are significantly lowered.

- Increased accuracy: Automation ensures accurate order fulfilment, improving customer satisfaction.

- Scalability: Easily adapt to fluctuating demands by scaling your automated systems.

Key components of an automated conveyor system in a warehouse

Central to automation success are key components that drive efficiency and innovation:

- Automated hardware: From order-picking solutions to storage and distribution operations, a range of automated machinery enhances accuracy and productivity.

- Warehouse Control System (WCS): Orchestrates operations, synchronising equipment and ensuring seamless workflow.

- Integration: Unify your Warehouse Management System (WMS) with WCS to optimise your automation project’s heartbeat.

Automated Warehouse Conveyor Systems

Unlock the potential of distribution systems through automation, redefining how products reach customers.

How Warehouse Automation Can Revolutionise Your Processes:

Automation’s impact on distribution is monumental, yielding benefits such as:

- Swift order fulfilment: Automated systems expedite the order-to-delivery process, meeting customer demands faster.

- Error minimisation: Automation eliminates manual handling errors, ensuring accurate product shipments.

- Real-time tracking: Gain real-time visibility into your distribution process, enhancing transparency and customer communication.

- Cost efficiency: Efficient, automated processes optimise resource allocation and reduce operational costs.

Warehouse Distribution

In the digital age, the connection between warehouse and distribution centre solutions is stronger than ever. Seamlessly integrated:

- Efficient logistics: Automated warehousing feeds seamlessly into automated distribution, creating a streamlined end-to-end process.

- Customer satisfaction: Quicker, error-free deliveries lead to satisfied customers and brand loyalty.

- Data-driven insights: Automation generates data that informs both warehousing and distribution strategies, driving continuous improvement.

Experience the future of warehouse distribution, where automation converges with intelligent strategies to revolutionise your operations. Elevate your supply chain, reduce costs, and drive growth with CSL’s expertise and innovation.

The ROI of Distribution and Warehouse Automation Systems

Over time, you can benefit from the substantial cost savings an automated process offers through reduced labour costs, operational inefficiencies, and error-related costs.

CSL can help you achieve improved accuracy and reduced error rates as automation avoids human errors, ensuring accurate order fulfilment and leading to improved customer satisfaction.

Tailored Warehouse Conveyor Solutions For Your Needs

At CSL, we pride ourselves on delivering adaptable and versatile solutions that cater to your specific demands.

Our offerings seamlessly align with the requirements of diverse business scales and types, whether you’re a nimble start-up or a well-established enterprise.

With a focus on adaptability and customisation, we ensure that our warehouse conveyor solutions perfectly match your unique requirements, fostering efficiency and growth across the board. Find out more about our bespoke warehouse automation solutions

Modern Warehouse & Distribution Centre Automation FAQs

What types of businesses benefit from warehouse automation?

Warehouse automation enhances operational efficiency and reduces costs for a wide range of businesses, from small startups to large enterprises.

How does automated warehousing improve inventory management?

Automated warehouse systems provide real-time tracking and accurate inventory control, minimising waste and stockouts while optimising stock levels.

Are automated systems adaptable to changing business needs?

Yes, automated systems are designed to be flexible and scalable, adapting to evolving demands, increasing efficiency, and accommodating growth.

How does real-time monitoring impact decision-making?

Real-time monitoring offers actionable insights, empowering informed decisions that lead to continuous improvements in efficiency and effectiveness.

What role does CSL play in implementing automation solutions?

CSL is your expert partner in warehouse and distribution centre automation, from system design and integration to delivering comprehensive solutions that elevate your operations.

Our Automation & Conveyor Solutions

We work closely with the industry leaders in conveyor and automation systems to provide the quality, reliability and durability required. Ensuring all projects are completed to the highest possible standard.

We have a wide range of modular and bespoke conveyor systems to provide customers with maximum flexibility, tailoring designs to your individual handling applications and budgets. Layouts can be designed to integrate with existing conveyor systems and associated equipment.

Our conveyor system project team can assess individual requirements, however complex, and then design and construct the most efficient solution whilst remaining cost-effective and within budget.

Belts and Conveyors

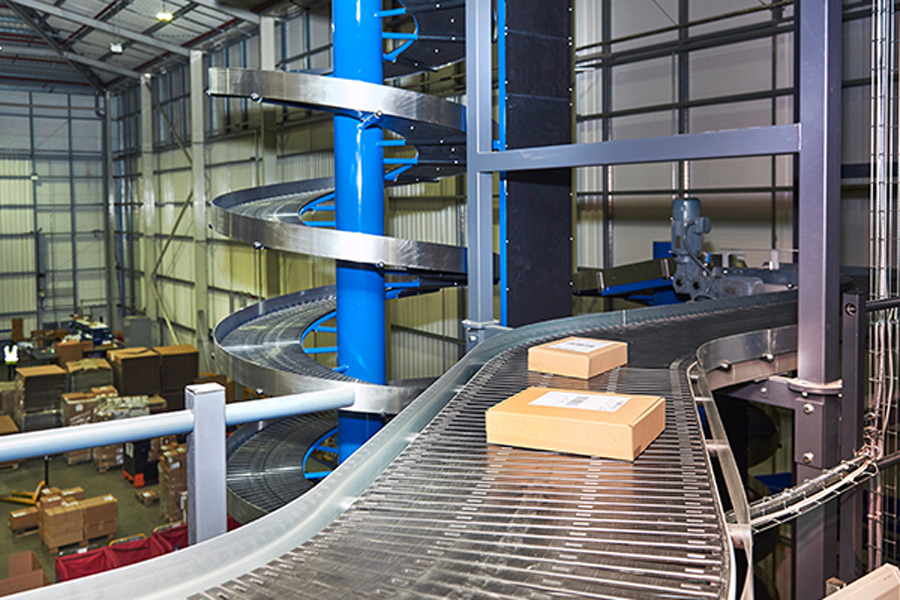

Spiral Conveyors

Automated Sortation

Automated Packing

Pallet Conveyors

Vertical Storage

AMRs

Vertical Lifts

Mezzanines, goods lifts & pallet racking

Latest Blog Posts

The benefits of Pick to Light

Pick to Light can be a game changer for yor facility when it comes to swift and accurate order picking.

Integrators vs. Manufacturers

When embarking on an automation project, one of the fundamental choices you’ll need to make is between working with an integrator or a manufacturer.

Enhance your 2025 automation strategy: Boost throughput, accuracy, and speed

With 2025 soon to be upon us the pressure on operations managers and directors to increase efficiency has never been higher.

Prepare your systems for a smooth post-peak season with CSL automation’s health check services

As the post-peak season approaches imminently, it's crucial to ensure that your automation and conveyor systems are in top shape.

The benefits of Pick to Light

Pick to Light can be a game changer for yor facility when it comes to swift and accurate order

Integrators vs. Manufacturers

When embarking on an automation project, one of the fundamental choices you’ll need to make is between working with

Enhance your 2025 automation strategy: Boost throughput, accuracy, and speed

With 2025 soon to be upon us the pressure on operations managers and directors to increase efficiency has never

Prepare your systems for a smooth post-peak season with CSL automation’s health check services

As the post-peak season approaches imminently, it's crucial to ensure that your automation and conveyor systems are in top

How the UK budget’s National Insurance changes impact businesses

With the recent increase in National Insurance contributions, businesses with large manual workforces face higher employment costs. CSL Automation

The risks of a broken or damaged conveyor system

We understand that you are constantly seeking ways to improve operational efficiency and reduce costs. So why would you

Creating relationships that last

We are proud to have completed installations over more than 25 years for many major organisations. We have forged strong relationships and continue to provide automation solutions through ongoing maintenance or follow-on projects. Constantly working with our customers to meet and exceed their needs.

“I have found working with CSL the ideal partnership, they understood the brief and worked closely with CEF to ensure the design met all of the criteria. The support from start to finish was excellent. The project ran smoothly from start to finish. The system has made our new warehouse very efficient and allowed us to increase the throughput”

“As this was a new facility it was difficult to visualise the conveyor system prior to the mezzanine floor installation, but CSL provided a detailed 3D drawing which included both the mezzanine and the conveyors which brought clarity to this. The install process was smooth and the end results have allowed us to increase control, flexibility & volumes”

“We have worked with CSL previously and after many years of reliable operation we decided to use CSL again to design, supply and carry out the installation. As with the last system the benefits became almost immediately evident”