ECommerce & Fulfillment Solutions and Automation

Keeping up with the clicksSolutions for eCommerce

In the fast paced eCommerce sector the importance of fulfilling all of your orders efficiently and accurately is paramount, conveyors and automation play a big part in this.

We combine cutting-edge conveyors and state-of-the-art automation to create streamlined fulfilment systems. All being tailor-made for the eCommerce sector and your business.

Automation systems are not just about speed but consistency. Ensuring that every package and order embodies your brand’s promise to your customers. Our automation solutions help eCommerce companies elevate their fulfilment game to the next level, while also turning challenges into opportunities.

Benefits

- Efficiency Boost: Rapidly process orders & reduce the time between purchase and dispatch.

- Improve Accuracy: Minimise human error, ensuring every order is fulfilled correctly the first time.

- Scalability: Our systems adapt to your growth, whether seasonal spikes or long-term expansion.

- Cost Savings: Reduce overheads with automated processes that reduce manual intervention and inefficiencies.

- Space Optimisation: Maximise your warehouse space and utilise every square inch effectively.

- Customer Satisfaction: Quicker and more accurate deliveries mean happier customers and repeat business.

- Flexible Integration: Seamlessly integrate with existing systems, ensuring a smooth transition and cohesive operations.

ECommerce warehouse: Beyond storage

eCommerce warehouses have evolved beyond storage spaces, they are now hubs of activity and productivity. At the heart of these facilities lie key components such as inventory management, order picking, packing, and dispatch, each crucial in seamless order fulfilment.

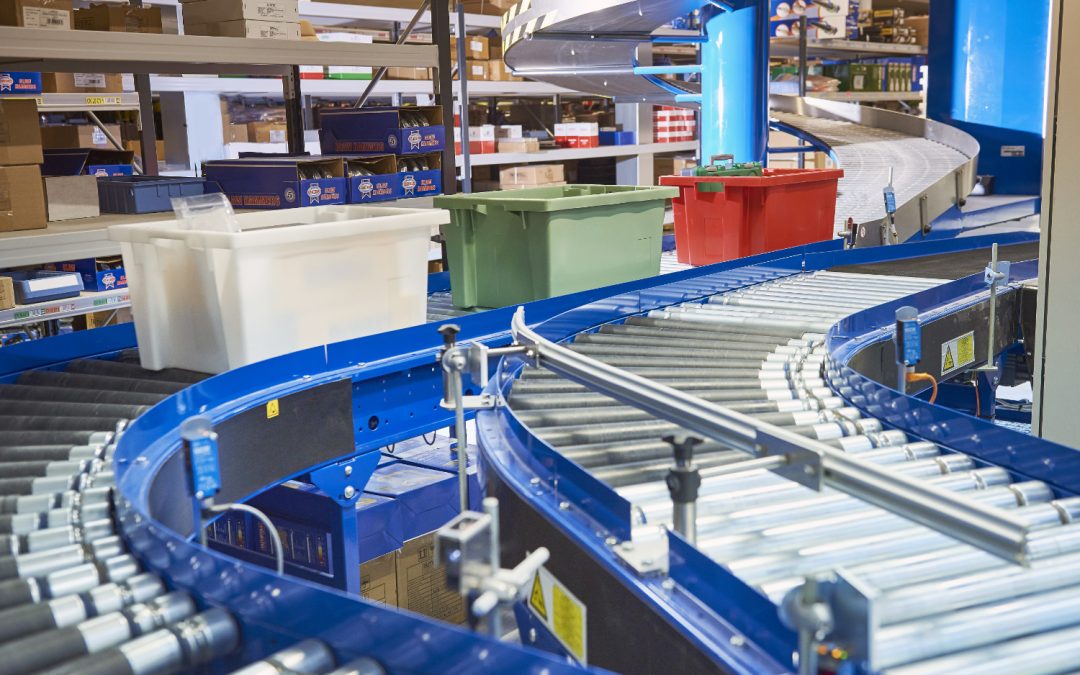

Our conveyor and automation systems resolve the challenges of moving goods between multi-level mezzanine storage, also simplifying product movements and providing seamless integration between different warehouse zones/functions.

Products are no longer just “stored”; they are strategically positioned, accessed and promptly dispatched. Embrace the future of warehousing, where storage meets sophistication.

Streamlining online order processing

The gears of online order processing require attention to detail to succeed. From the moment a customer clicks ‘purchase’ to the joy of unboxing, every stage must be quick and seamless. Our advanced conveyor systems and automation technologies elevate each step of this journey:

- Order picking: Navigate warehouse spaces easily, finding and retrieving products quickly with automated conveyors.

- Order processing: With integrated software and hardware, the handling and sorting of orders are more streamlined than ever. Ensuring no order goes unnoticed or delayed.

- Packing: Automation ensures that products are packed securely and efficiently. Always in a manner that reflects the brand’s commitment to excellence.

- Shipping: Dispatch systems align with conveyors for a seamless transition. Speeding up the shipping process and ensuring timely deliveries.

- Returns processing: Simplify the returns journey. Ensure items are quickly received, inspected and processed, keeping inventory and customer satisfaction at their peak.

Adapting to demand: Scalable solutions for peak times

Peak seasons like holiday sales, Black Friday and end-of-season clearances magnify the already intense demands of order fulfilment. Such high-demand periods need not just speed but adaptability.

Our automation and conveyor systems offer an unparalleled ability to scale up operations. Adapting to the surges of the holiday frenzy or a flash sale.

But why is scalability so crucial? Because in the realm of eCommerce fulfilment, staying static is falling behind. We have the capability to expand or contract, depending on order volume. This ensures efficiency, cost-effectiveness, and unwavering customer satisfaction. With our scalable solutions, you’re not just meeting the demands of peak times but setting the standard in adaptive eCommerce operations.

eCommerce & fulfillment solutions and automation FAQs

What differentiates CSL's automation and technology from other providers?

CSL’s solutions are tailored to tackle the unique challenges of today’s ECommerce world. Our technology is not just advanced but also modular. This means our systems are flexible, ensuring they can manage both traditional business needs and adapt swiftly. Particularly during seasonal peaks, irregular demands, and growth spurts.

Why is scalability so crucial in eCommerce fulfillment?

ECommerce operations can face varying demand levels, from regular orders to seasonal spikes or flash sales. Scalability ensures your fulfillment processes can adapt to fluctuations without compromising efficiency, cost, or customer satisfaction. A scalable system is future-proof, ready to accommodate growth and changing market dynamics.

How do CSL's systems adapt to high-demand periods like holiday seasons?

With our modular approach, CSL’s systems are built to scale up or down based on demand. This means our solutions can be swiftly adapted to handle increased volumes during high-demand periods, like holiday sales or Black Friday, ensuring consistent performance and timely deliveries.

Can I integrate CSL's solutions with my existing warehouse management systems?

Absolutely. CSL’s solutions are engineered for seamless integration with various warehouse management systems. This ensures cohesive operations, a smooth transition, and optimal performance across all processes.

Our Automation & Conveyor Solutions

We work closely with the industry leaders in conveyor and automation systems to provide the quality, reliability and durability required. Ensuring all projects are completed to the highest possible standard.

We have a wide range of modular and bespoke conveyor systems to provide customers with maximum flexibility, tailoring designs to your individual handling applications and budgets. Layouts can be designed to integrate with existing conveyor systems and associated equipment.

Our conveyor system project team can assess individual requirements, however complex, and then design and construct the most efficient solution whilst remaining cost-effective and within budget.

Belts and Conveyors

Spiral Conveyors

Automated Sortation

Automated Packing

Pallet Conveyors

Vertical Storage

AMRs

Vertical Lifts

Mezzanines, goods lifts & pallet racking

Latest Blog Posts

How to justify having a service contract for your business

A key component of safeguarding automation systems is having a robust service contract in place.

Customising maintenance plans with CSL Automation’s ConveyorCare

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and lost revenue.

Hybrid Fulfilment: Revolutionising retail with automation

Supported by cutting-edge automation, hybrid fulfilment enables businesses to achieve efficiency, flexibility, and scalability while delivering exceptional customer experiences.

Is now the right time for a new conveyor and automation system?

As we step into a new year, it’s the perfect time to reflect on operational efficiencies and plan ahead for the challenges and opportunities that lie ahead.

How to justify having a service contract for your business

A key component of safeguarding automation systems is having a robust service contract in place.

Customising maintenance plans with CSL Automation’s ConveyorCare

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and

Hybrid Fulfilment: Revolutionising retail with automation

Supported by cutting-edge automation, hybrid fulfilment enables businesses to achieve efficiency, flexibility, and scalability while delivering exceptional customer experiences.

Is now the right time for a new conveyor and automation system?

As we step into a new year, it’s the perfect time to reflect on operational efficiencies and plan ahead

Keeping operations running smoothly post peak

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and

The risk of not having automation in eCcommerce, 3PL, and Fulfilment Centres

In our latest blog, we explore the 8 key advantages of adopting automation for your operations

Creating relationships that last

We are proud to have completed installations over more than 25 years for many major organisations. We have forged strong relationships and continue to provide automation solutions through ongoing maintenance or follow-on projects. Constantly working with our customers to meet and exceed their needs.

“I have found working with CSL the ideal partnership, they understood the brief and worked closely with CEF to ensure the design met all of the criteria. The support from start to finish was excellent. The project ran smoothly from start to finish. The system has made our new warehouse very efficient and allowed us to increase the throughput”

“As this was a new facility it was difficult to visualise the conveyor system prior to the mezzanine floor installation, but CSL provided a detailed 3D drawing which included both the mezzanine and the conveyors which brought clarity to this. The install process was smooth and the end results have allowed us to increase control, flexibility & volumes”

“We have worked with CSL previously and after many years of reliable operation we decided to use CSL again to design, supply and carry out the installation. As with the last system the benefits became almost immediately evident”