Bespoke Automations, Conveyors and Solutions

Solutions tailored to your needsIn today’s environments of eCommerce and warehousing, the need for adaptable automation has never been more crucial. At CSL, we recognise that no two industrial challenges are the same and not all ‘off the shelf’ equipment and technology can address the business challenge you face. This is why we champion the concept of Bespoke Automation, the creation of bespoke equipment to resolve your specific needs.

Bespoke Automation equipment can help in overcoming space issues, optimising vertical movement, enhancing flexibility and more. With our proven technology at our core, CSL is your trusted partner in crafting bespoke handling and machinery solutions. Ones that adapt seamlessly to your unique industrial needs.

Delving into bespoke systems

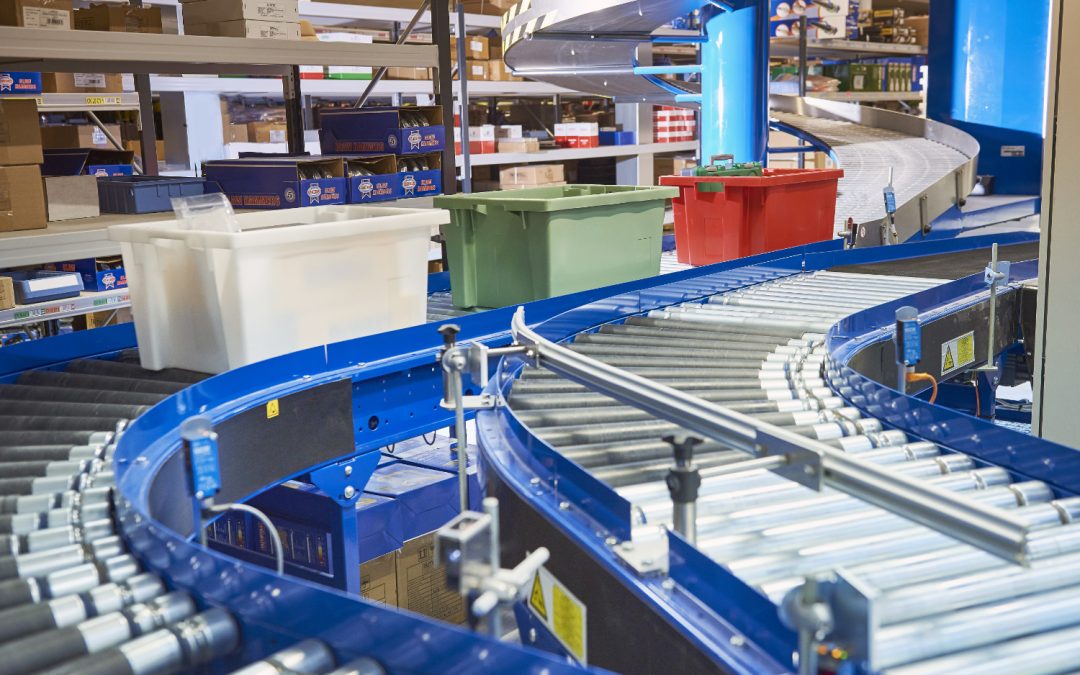

Bespoke conveyor and automation systems provide significant advantages over off-the-shelf equipment by offering tailored solutions that meet the exact requirements of your operations. For industries handling heavy, bulky, or awkwardly shaped items, custom-built conveyors are crucial for safely and efficiently moving materials that would be difficult or hazardous to handle manually.

Equipment like heavy-duty roller conveyors, pallet conveyors, and automated sorting systems can be designed to handle large loads and streamline processes that might otherwise be slow, unsafe, or prone to errors.

For items that are sharp, fragile, or pose a safety risk during manual handling, bespoke systems can integrate protective features and automation technologies that minimize human intervention, reduce the risk of injury, and improve overall operational efficiency.

We commit to ensuring that our hardware and software work in harmony with your solutions.

Why Choose CSL?

We have expertise in delivering both standard and bespoke automation tailored to your needs. With a rich history of designing, manufacturing, and installing systems, we can tackle any application challenges.

Our commitment to excellence extends to our close partnerships with other industry leaders. These ensure your project benefits from reliable, durable, and high standards.

We offer a range of modular and custom conveyor solutions. This gives you the flexibility to align with your handling requirements and budget constraints. Our designs integrate with existing systems and associated equipment, enhancing your facility’s efficiency.

Our dedicated team specialises in assessing individual requirements, no matter how complex. We then craft the most efficient, cost-effective, and budget-conscious solutions. Choose us as a trusted partner in elevating your automation endeavours to new heights.

FAQs

What is bespoke automation?

Bespoke automation refers to custom automation that meet the requirements of a business. Unlike off-the-shelf solutions, these are designed for the unique challenges and needs of an industry or process.

How does bespoke handling differ from standard handling solutions?

Bespoke handling is tailored to your needs, ensuring efficient, optimal and seamless operations. Standard solutions, while effective, might not cater to the unique constraints of your business.

Why should I consider bespoke machinery for my business?

Bespoke machinery ensures that the equipment aligns with your operational needs. This also reduces the need for many machinery or workarounds that might be necessary with generic solutions.

Are bespoke conveyor systems more expensive than off-the-shelf options?

The initial investment for bespoke systems may be higher but they offer long-term savings. This is by reducing maintenance costs, increasing efficiency, and removing the need for more equipment.

Can I upgrade my current system with bespoke automation solutions?

Absolutely! We specialise in integrating bespoke solutions into existing operations. This ensures a seamless transition and optimal performance enhancement.

How do I know if bespoke automation is right for my business?

Our experienced team offers consultations to understand your requirements. We can then recommend the best solutions. If standard systems don’t address your challenges, bespoke automation is often the ideal choice.

Our Automation & Conveyor Solutions

We work closely with the industry leaders in conveyor and automation systems to provide the quality, reliability and durability required. Ensuring all projects are completed to the highest possible standard.

We have a wide range of modular and bespoke conveyor systems to provide customers with maximum flexibility, tailoring designs to your individual handling applications and budgets. Layouts can be designed to integrate with existing conveyor systems and associated equipment.

Our conveyor system project team can assess individual requirements, however complex, and then design and construct the most efficient solution whilst remaining cost-effective and within budget.

Belts and Conveyors

Spiral Conveyors

Automated Sortation

Automated Packing

Pallet Conveyors

Vertical Storage

AMRs

Vertical Lifts

Mezzanines, goods lifts & pallet racking

Latest Blog Posts

How to justify having a service contract for your business

A key component of safeguarding automation systems is having a robust service contract in place.

Customising maintenance plans with CSL Automation’s ConveyorCare

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and lost revenue.

Hybrid Fulfilment: Revolutionising retail with automation

Supported by cutting-edge automation, hybrid fulfilment enables businesses to achieve efficiency, flexibility, and scalability while delivering exceptional customer experiences.

Is now the right time for a new conveyor and automation system?

As we step into a new year, it’s the perfect time to reflect on operational efficiencies and plan ahead for the challenges and opportunities that lie ahead.

How to justify having a service contract for your business

A key component of safeguarding automation systems is having a robust service contract in place.

Customising maintenance plans with CSL Automation’s ConveyorCare

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and

Hybrid Fulfilment: Revolutionising retail with automation

Supported by cutting-edge automation, hybrid fulfilment enables businesses to achieve efficiency, flexibility, and scalability while delivering exceptional customer experiences.

Is now the right time for a new conveyor and automation system?

As we step into a new year, it’s the perfect time to reflect on operational efficiencies and plan ahead

Keeping operations running smoothly post peak

The health of your conveyor and automation systems is vital. Downtime can result in missed deadlines, dissatisfied customers, and

The risk of not having automation in eCcommerce, 3PL, and Fulfilment Centres

In our latest blog, we explore the 8 key advantages of adopting automation for your operations

Creating relationships that last

We are proud to have completed installations over more than 25 years for many major organisations. We have forged strong relationships and continue to provide automation solutions through ongoing maintenance or follow-on projects. Constantly working with our customers to meet and exceed their needs.

“I have found working with CSL the ideal partnership, they understood the brief and worked closely with CEF to ensure the design met all of the criteria. The support from start to finish was excellent. The project ran smoothly from start to finish. The system has made our new warehouse very efficient and allowed us to increase the throughput”

“As this was a new facility it was difficult to visualise the conveyor system prior to the mezzanine floor installation, but CSL provided a detailed 3D drawing which included both the mezzanine and the conveyors which brought clarity to this. The install process was smooth and the end results have allowed us to increase control, flexibility & volumes”

“We have worked with CSL previously and after many years of reliable operation we decided to use CSL again to design, supply and carry out the installation. As with the last system the benefits became almost immediately evident”